Our Grob Cold Rolling Process is a cold-forming process where a metal workpiece is formed with rolls at ambient temperature. Cold forming provides several benefits to manufacturers, including high strength and low internal stress. These features make cold-formed products ideal for CNC machining, producing final shapes and end products with excellent mechanical properties.

Grob Inc. delivers high-quality cold-formed products for the industrial and manufacturing industry. Understanding the applications of cold-formed products, the materials used, and their benefits will help you determine if cold-formed products are ideal for your project.

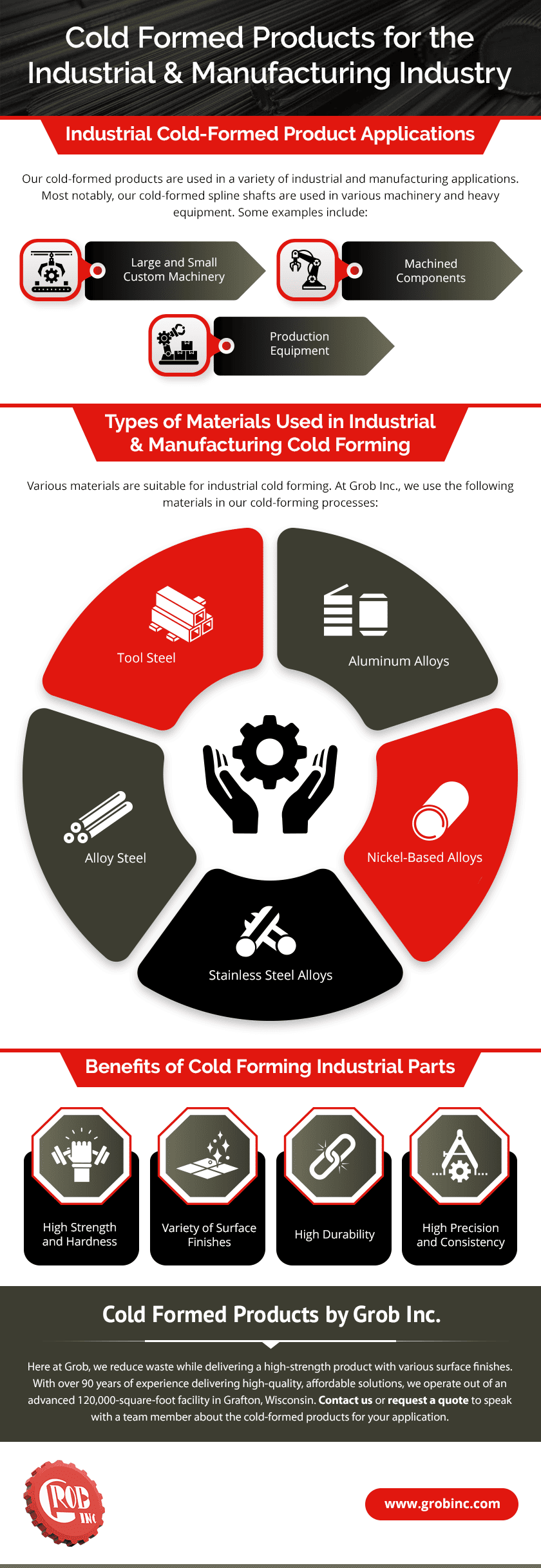

Industrial Cold-Formed Product Applications

Our cold-formed products are used in a variety of industrial and manufacturing applications. Most notably, our cold-formed spline shafts are used in various machinery and heavy equipment. Some examples include:

- Large and Small Custom Machinery: Cold-formed steel products have a modified grain structure, making them up to 20% stronger than normal steel and offering durability suitable for custom production equipment and machinery. Examples include corrugated machinery, pump trucks, and extrusion machines.

- Machined Components: Cold-formed steel can be used in more CNC machining and finishing processes to create a range of products. These can be splines, gears, and pulleys that are up to 20% stronger.

- Production Equipment: High-movement production equipment requires the durability cold-formed steel provides to withstand constant use and wear. These can be found in conveyor systems, cranes, forklifts, and other material-handling equipment.

Types of Materials Used in Industrial & Manufacturing Cold Forming

Various materials are suitable for industrial cold forming. At Grob Inc., we use the following materials in our cold-forming processes:

- Aluminum Alloys

- Nickel-Based Alloys

- Stainless Steel Alloys

- Alloy Steel

- Tool Steel

Benefits of Cold Forming Industrial Parts

Cold forming delivers several benefits to industrial parts used in manufacturing and industrial processes. The primary benefits of cold forming include the following:

- High Strength and Hardness: Cold rolled steel offers 20% more strength than standard metal cutting processes, producing components that can withstand high-stress conditions.

- Variety of Surface Finishes: Cold-formed steel products have a smooth, shiny surface finish. This makes them ideal for tight tolerance applications that require minimal backlash and smooth sliding in the application.

- High Durability: Production machinery and components must constantly run for millions of cycles. The high durability of cold-formed components keeps the manufacturing process running smoothly. With a harder surface but still a ductile core, cold forming creates extremely robust parts.

- High Precision and Consistency: Cold-formed components hold very consistent sizes over a very long production run. This allows for very precise and accurate parts and final assemblies.

Cold Formed Products by Grob Inc.

Industrial and manufacturing industries depend on cold-formed products for their high strength, hardness, durability, and precision. Cold-formed steel can produce small and large machinery, production equipment, and machined components from various alloys, such as stainless steel and titanium.

Here at Grob, we reduce waste while delivering a high-strength product with various surface finishes. With over 90 years of experience delivering high-quality, affordable solutions, we operate out of an advanced 120,000-square-foot facility in Grafton, Wisconsin. Contact us or request a quote to speak with a team member about the cold-formed products for your application.