Advantage

Cold Rolled Strength & Surface Finish

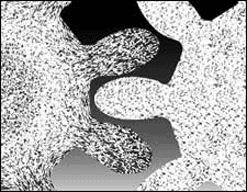

The Grob Rolling process increases the strength by rearranging the grain structure of the material over the entire tooth profile. The greatest amount of strength is gained near the bottom, or root area of the form where strength is most crucial. Note the tighter grain structure of a cold rolled tooth form (left) as compared to that of a cut gear (right). The result of the cold forming process produces a very high surface finish. Roughness average, (Ra) Readings of 4 micro inches have been produced.

Grob Rolling Method

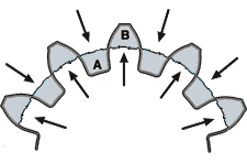

With Grob cold forming, the groove is formed down between the teeth. The material displaced from area “A” (see sketch below) forms the tooth tip area “B”. This is a severe reverse flow. With no elongation, the area of raw material displaced must be the exact same as the area it was displaced from.

Through this process, we’re able to roll both even and uneven numbers of teeth on a cylindrical blank with symmetrical patterns only. Tubular blanks can be formed over a grooved mandrel, which permits internal corrugation of the blank white external shape is rolled.

Material & Solid Blank Preparation

Because the Grob Rolling process displaces material instead of removing it, proper material selection is important. With this process, almost any ductile material may be used. Generally, material with a hardness of less than Rockwell “C” 30 works well. If carbon steel or alloy steel is to be used, it must be annealed first. The blank or stock must be free of flaws, uniform in ductility, and must be the correct outside diameter to produce an accurate form.

Cold Rolled Strength Through Innovation

Work hardening of the cold rolled form depends on the material composition, the hardness before rolling, the depth of the tooth form, and the feed rate of rolling. Not all material works well for the same shape. For example, aluminum and some stainless steels may be formed to produce a spline shape or shallow tooth form, but may not be used to produce a full depth gear because the material work hardens too quickly and will not flow up to fill in the tooth form.