Grob Inc. serves the agriculture industry with superior-quality cold-forged products. Our innovative production method allows us to create components with high-precision profiles and virtually no wasted material. If you can’t find the product you need in our catalog of over 2,100 profiles, our team will develop a custom profile to your exact specifications. Our cold forging process, or Grob Rolling process, for agricultural parts involves formed tooling that strikes the bar at precise locations to displace material, resulting in a high-strength product with improved surface quality.

Agricultural Cold Formed Product Applications

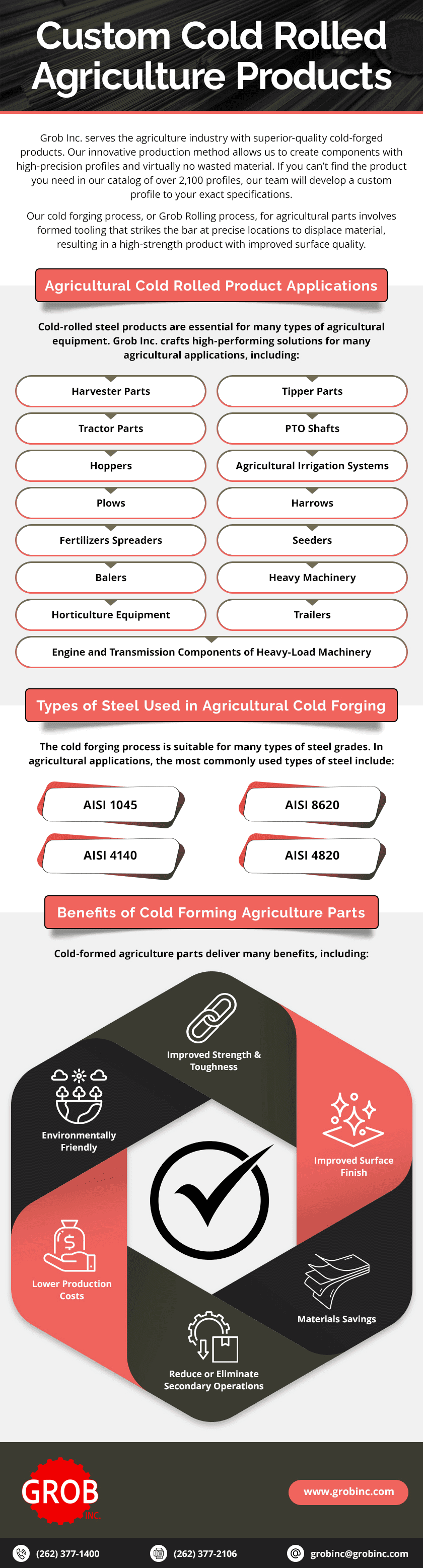

Cold-formed steel products are essential for many types of agricultural equipment. Grob Inc. crafts high-performing solutions for many agricultural applications, including:

- Harvester Parts

- Tipper Parts

- Tractor Parts

- PTO Shafts

- Hoppers

- Agricultural Irrigation Systems

- Plows

- Harrows

- Fertilizers Spreaders

- Seeders

- Balers

- Engine and Transmission Components of Heavy-Load Machinery

- Heavy Machinery

- Horticulture Equipment

- Trailers

Steel is a widely used material for farm machinery and agricultural equipment. It is valued in these applications as it is known for its strength and durability. There are many grades of steel to choose from to fit the demand and needs of a part. Different post-processing methods can be used to increase the desired mechanical properties of the steel such as toughness, hardness, and corrosion resistance.

Types of Steel Used in Agricultural Cold Forging

The cold forging process is suitable for many types of steel grades. In agricultural applications, the most commonly used types of steel include:

- AISI 1045: This is a great low-cost medium-carbon steel with good mechanical properties. This material can be heat treated with several different methods.

- AISI 8620: With great carburizing abilities, this steel is great for medium-strength applications that require carburizing as a post-process treatment.

- AISI 4140: A medium-carbon steel with excellent properties in hardenability, fatigue, and abrasion and impact resistance.

- AISI 4820: This steel is a great option when maximum toughness and core strength are needed. This low-carbon alloy steel will result in very tough, long-lasting parts.

Benefits of Cold Forming Agriculture Parts

Cold-formed agriculture parts deliver many benefits, including:

- Improved Strength and Toughness: Compared to machined components, cold-formed parts result in improved mechanical properties, such as improved toughness, tensile strength, and hardness. The finished components will be stronger, extending the lifespan of the equipment.

- Improved Surface Finish: The Grob Rolling method provides a very smooth surface finish that allows moving products to fit seamlessly together with less friction.

- Lower Production Costs: Cold-forging uses precision-engineered tooling that allows for high speed forming with less material than cutting methods. This saves time and money resulting in a high-strength, low-cost solution.

- Materials Savings: Grob Inc.’s precision cold-forming process results in no waste materials, meaning less material is needed to manufacture the same part. This reduces the raw material cost for each part.

- Reduce or Eliminate Secondary Operations: With cold forming, the material is formed into the desired shape with exceptional properties, eliminating the need for some post-processing such as heat treating and grinding. Grob Inc. bar stock gets you closer to your finished part faster, reducing costs.

- Environmentally Friendly: Compared to other manufacturing techniques, cold forming reduces energy consumption and waste materials, resulting in greater resource efficiency as well as cost savings.

Cold-Formed Agriculture Products From Grob Inc.

Grob Inc.’s cold-formed products for the agriculture industry are backed by nearly a century of innovation. Our precision cold forming process is suitable for several metal varieties and shapes, from shallow tooth forms to full-depth gears. If you have any questions, get in touch with our team. You can get started on your solution by requesting a quote today.