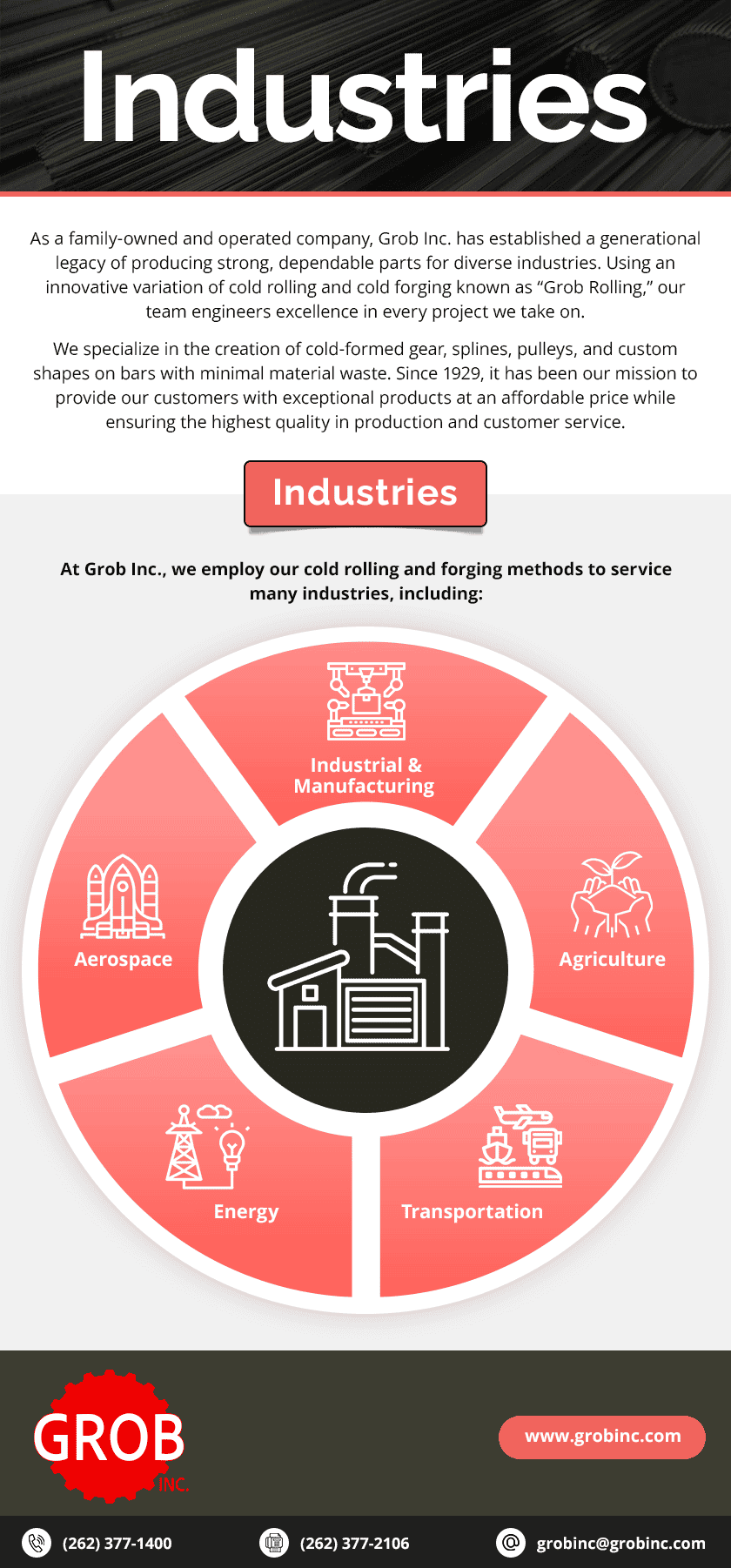

As a family-owned and operated company, Grob Inc. has established a generational legacy of producing strong, dependable parts for diverse industries. Using an innovative variation of cold forming and cold forging known as “Grob Rolling,” our team engineers excellence in every project we take on.

We specialize in the creation of cold-formed gear, splines, pulleys, and custom shapes on bars with minimal material waste. Since 1929, it has been our mission to provide our customers with exceptional products at an affordable price while ensuring the highest quality in production and customer service.

Grob cold formed products have several advantages over hot forging or machined parts, including:

- Smoother surface finish

- Better mechanical properties

- Enhanced productivity

- Dimension control

- Speed

- Customizability

- Low-waste

At Grob Inc., we employ our cold forming and forging methods to service many industries, including:

Transportation

The transportation sector is one of the major users of gears, pulleys, and splines. They will be found throughout the vehicle from the engine to the axles. This is true for all sectors of transportation including rail and trucking. Grob supplies components for the steering column to drive lines. Grob’s products with superior strength and surface finish can be supplied in bar stock or finished machined parts.

Agriculture

Much like the transportation industry the agriculture industry has many uses for gears, splines, and pulleys. The agricultural industry also utilizes custom shapes like squares, hex, and lobed profiles. Some systems that commonly contain these components are axles, transmission, PTO shafts, and hydraulic systems. Grob is a leading supplier of PTO shaft splines. Grob’s added strength and surface finish will generate a robust shaft that will transfer power smoothly over any terrain. Grob can generate a spline of any length and shape for our customers’ needs.

Some common PTO splines shafts that Grob produces

- SAE standard spline (4 spline – 16 spline)

- ISO standard spline (6 spline – 10 spline)

- Involute splines (1” 15T – 1.75” 20T)

- Square

- Hex

- Grob Straight Sided spline (1 5/16” – 20 spline to 1 ⅞”-20 spline)

- Lobe profile solid and tubes

Energy

The energy of industry primarily uses profiled or fluted tubing in heat exchanges. These heat exchangers are used in refineries to make all sorts of chemicals, oils, and fuels. In addition, fluted tubing can also be used in desalination systems. The benefit of fluted tubes is the added surface area to increase efficiency. Grob’s process is unique because it creates the profile on the inside and outside of the tube. It also creates a thinner tube than other methods. It has been seen that using a fluted tube will decrease the size of the heat exchanger offsetting the price of the fluting process. Grob can also make fluted tubes from steel, copper, and brass tubes at 20-foot lengths. Grob supplies you with high-quality fluted tubing that provides energy throughout the world.

Aerospace

Weight and strength are keys in the Aerospace industry. Most components are made of aluminum, plastics, or harder metals like titanium and inconel. Grob produces a large number of aluminum splines and profiles that are used in aerospace components. These can then be mated with plastic components that we machine and broach in our machine shop. Grob also has the ability to profile materials up to 44 HRC. This allows components to be made smaller to minimize weight while not sacrificing strength and durability. From interior parts to critical structural and mechanical components, Grob will be able to supply whatever your needs might be.

Industrial & Manufacturing

When it comes to these industries it’s all about strength and durability. These industries require components that will withstand millions of cycles and be reliable 24-7. This includes custom splines and gears for custom product machines to small pulleys found in printers and smaller industrial machines. Grob can produce a wide range of products for a 20ft spline shaft out of 17-4 stainless to a ¼” aluminum pulley for a printer. Grob also produces lobed shapes that go into hydraulic pumps and motors. Grob will make your product stronger no matter what.

Cold Formed Products & Band Saws from Grob, Inc.

Cold forging produces stronger & more reliable products that can achieve peak performance throughout their working life cycles. At Grob, Inc., our dedication to innovation and quality allows us to produce cold-forged products with high-quality finishes that exceed our customers’ expectations. Contact Grob, Inc. to begin your order or request a quote for your design!