Centerless Bar Grinding Services Latest

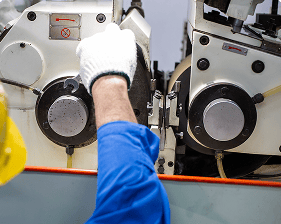

High-Volume, High-Precision Grinding Without Centers

Grob Inc. offers centerless grinding services ideal for cylindrical parts requiring tight OD tolerances and superior surface finishes. This method eliminates the need for part centering, enabling faster throughput and reduced setup time.

Applications: Shafts, pins, rods, bushings, and bearing components

Capabilities: In-feed and through-feed grinding, diameters from 0.050″ to 6“

Advantages: High-speed production, consistent concentricity and roundness, minimal deflection

Example Projects

Precision dowel pins

Ground to ±0.0002" for aerospace assembly

Bearing sleeves

High-volume production with concentricity control

guide rods

Stainless steel rods with mirror finish

FAQs

What’s the difference between in-feed and through-feed grinding?

In-feed is used for parts with complex shapes; through-feed is ideal for simple cylindrical parts.

Can you grind hardened materials?

Yes, we routinely grind hardened steels and alloys.

What industries do you serve with centerless grinding?

Aerospace, medical, automotive, and industrial manufacturing.

Our centerless grinding process is optimized for repeatability and efficiency, making it perfect for high-volume manufacturing. Partner with Grob Inc. for precision grinding that meets your toughest specs.