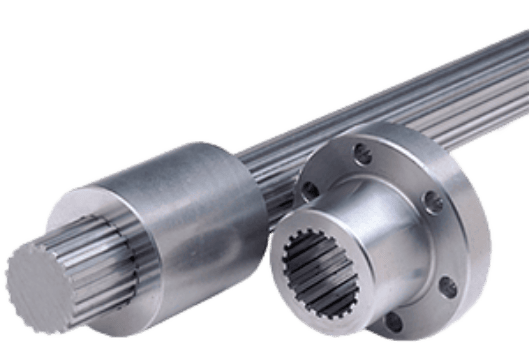

Cold Formed/Forged Products Overview

Grob Inc. supplies a variety of cold formed products, including spline shafts, standard and custom timing belt pulleys, flanged bushings, broached sleeves, heat exchanger tubes and drums, and spur gears.We engineer excellence into every cold formed product, delivering stronger and more economical parts to end users. Learn more about the Grob Cold Rolling method, our cold formed products, the benefits of our cold forming process, and the custom machining services we offer.

The Grob Rolling Process

Originating in the 1950s as an alternative to hobbing (removing material by cutting), the Grob Rolling process displaces raw material to create a desired tooth shape, leaving little to no waste. The Grob Rolling process increases the strength of the material by creating a tighter grain structure over the entire tooth profile. The biggest strength gain is near the root area or bottom of the form, where it is typically the most crucial.

When using Grob Rolling, a severe reverse flow occurs where the groove forms down between the teeth. The displaced raw material must be the same as the area from where it originated. This cold forming process allows us to form even and uneven numbers of teeth with symmetrical patterns on cylindrical blanks. We can also form tubular blanks over grooved mandrels, creating internal corrugation of the blank while cold forming the external shape.

Suitable Metals for Cold Forming

The high-speed process of cold forming enables the manufacturing of large amounts of metal-based products in a quick, cost-effective, and consistent manner. Cold formed products have a superior surface finish, generate a greater yield, and feature higher tensile strength and hardness than products manufactured using heat forming.

While some materials, such as cast iron, are too brittle for the cold forming process, there is a variety of suitable materials, some of which include:

- Aluminum (2024, 6061)

- Stainless Steel (316, 416, 17-4)

- Most Materials up to 44 HRC

- Alloy Steel (1045, 1117, 1215, 4140, 4150, 4340, 8620, H1-11)

- Naval Brass

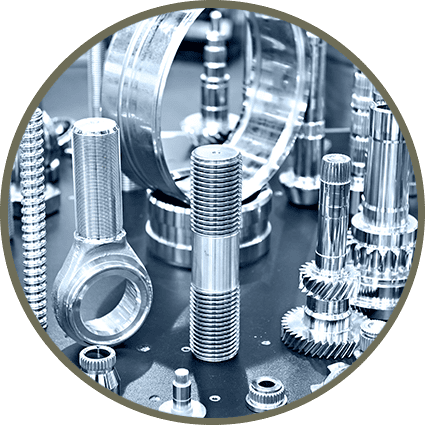

Custom Machining Services

Grob Inc. also offers CNC machining for finishing cold formed components or creating new components from bar stock. With our inspection lab and state-of-the-art machinery, we provide customers with superior quality, cost-effective products. Our CNC machining capabilities include the following:

- 5-Axis Milling

- OD Grinding

- Cutting

- Digital Optical Comparator

- Centerless Grinding

- Surface Grinding

- CMM

- Turning

Advantages of Our Cold Formed Products

To improve the mechanical and dimensional properties of hot rolled steel, the material undergoes cold forming. The cooled hot rolled steel passes through a series of room temperature rollers. Since the material is no longer hot, it loses its malleable properties, requiring considerable pressure to compress the form into its desired shape. Even though the process can be more expensive and labor-intensive than the hot rolling process, cold forming results in better surface qualities and tighter dimensional tolerances.

Cold rolled steel offers significant advantages over hot rolled steel, including:

Higher Strength

Cold rolled steel has 20% greater strength than hot rolled steel, making it better suited for high-stress applications.

Improved Surface Finish

Cold formed products typically have a smoother, shinier surface free of scale and rust.

More Precision

Cold rolled steel does not shrink when formed, which would occur with hot rolled steel. This property enables the manufacturing of precise parts requiring minimal secondary processing.

Contact Grob, Inc. for High-Quality Cold Formed Products

At Grob Inc., we have the knowledge, tools, and skills to create custom cold formed products for nearly any custom or standard application. As a family owned and operated company, we employ more than 60 engineers and technicians at our 100,000-square-foot headquarters and manufacturing facility in Grafton, Wisconsin.

Contact us today to learn more about our cold formed products and manufacturing capabilities. Request a quote for detailed pricing information pertaining to your specific application.