CNC Machining Services

Machining Capabilities

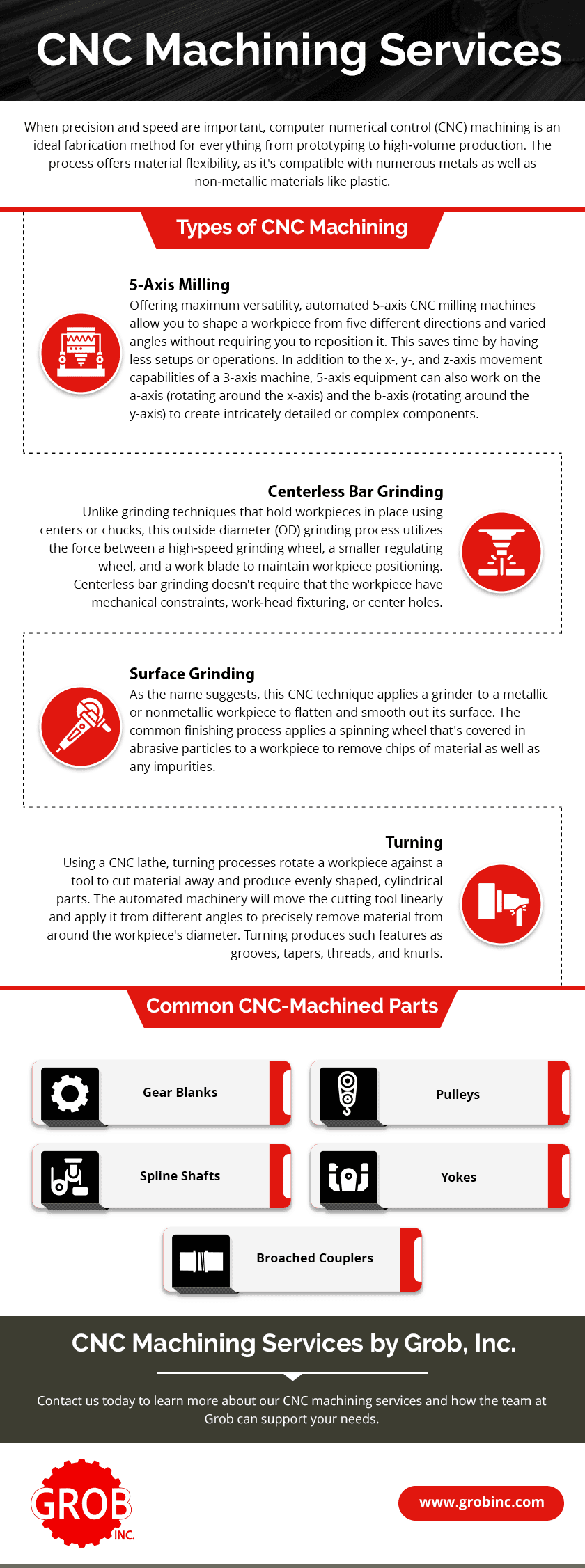

When precision and speed are important, computer numerical control (CNC) machining is an ideal fabrication method for everything from prototyping to high-volume production. The process offers material flexibility, as it’s compatible with numerous metals as well as non-metallic materials like plastic. Using computer-aided design and manufacturing (CAD/CAM) software, manufacturers convert a part’s design into digital instructions that automated CNC equipment will follow to precisely shape a part.

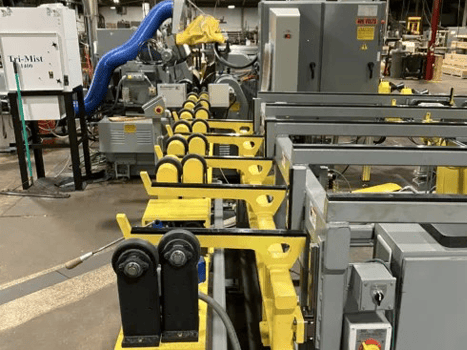

CNC equipment and tooling will carry out milling, turning, grinding, cutting, and other subtractive machining techniques with minimal human intervention to quickly generate repeatable, high-quality components of simple or complex designs. At Grob Inc., we offer an array of CNC machining services to meet your exacting product specifications and application requirements.

Types of CNC Machining

CNC machining is made up of many different subtractive machining processes for shaping a workpiece, creating a precision part in less time than it takes to machine products manually.

5-Axis Milling

Offering maximum versatility, automated 5-axis CNC milling machines allow you to shape a workpiece from five different directions and varied angles without requiring you to reposition it. This saves time by having less setups or operations. In addition to the x-, y-, and z-axis movement capabilities of a 3-axis machine, 5-axis equipment can also work on the a-axis (rotating around the x-axis) and the b-axis (rotating around the y-axis) to create intricately detailed or complex components.

Centerless Bar Grinding

Unlike grinding techniques that hold workpieces in place using centers or chucks, this outside diameter (OD) grinding process utilizes the force between a high-speed grinding wheel, a smaller regulating wheel, and a work blade to maintain workpiece positioning. Centerless bar grinding doesn’t require that the workpiece have mechanical constraints, work-head fixturing, or center holes.

Surface Grinding

As the name suggests, this CNC technique applies a grinder to a metallic or nonmetallic workpiece to flatten and smooth out its surface. The common finishing process applies a spinning wheel that’s covered in abrasive particles to a workpiece to remove chips of material as well as any impurities.

Turning

Using a CNC lathe, turning processes rotate a workpiece against a tool to cut material away and produce evenly shaped, cylindrical parts. The automated machinery will move the cutting tool linearly and apply it from different angles to precisely remove material from around the workpiece’s diameter. Turning produces such features as grooves, tapers, threads, and knurls.

Common CNC-Machined Parts

CNC machining processes are highly versatile, giving them diverse capabilities for creating an array of shapes and parts. Common components that are compatible with CNC machining processes and benefit from their precision include the following:

- Gear blanks. At the beginning of gear manufacturing operations, the process first generates gear blanks. Prior to heat treatments like broaching and hobbling, these blanks provide the input or initial product for gear production and affect the level of precision you can achieve in your gears.

- Pulleys. These widely used wheels have applications across industries, from industrial machinery and agriculture to material handling and conveyance. Machined with a groove to allow for belt placement around their circumference, pulleys facilitate heavy lifting and moving operations as they turn.

- Spline Shafts. Usually connecting to a broached sleeve our yoke allows for linear power transfer founding in many machines, vehicles, and heavy equipment.

- Yokes. Yokes serve as connectors between a driveshaft and components like the transfer case. In vehicles, they transfer power from the case to the shaft by slipping into and out of the transfer case, giving a driveshaft the flex necessary to manage varying or rough road conditions allows for changes in angle.

- Broached Couplers. Allows for sliding or fixed positions on a spline shaft to transfer rotating power.

CNC Machining Services by Grob, Inc.

Since 1929, Grob Inc. has been dedicated to quality, skilled craftsmanship, value, and customer satisfaction. Our family-owned and -operated company specializes in CNC-machined and cold-rolled products as well as vertical contour band saws. We provide custom machining services to fabricate and finish parts and components for industries as varied as agriculture, manufacturing, transportation, and energy. Using automated CNC machining, we strive to save you time and money while helping you drive growth and reach your operation’s goals.

Contact us today to learn more about our CNC machining services and how the team at Grob can support your needs.