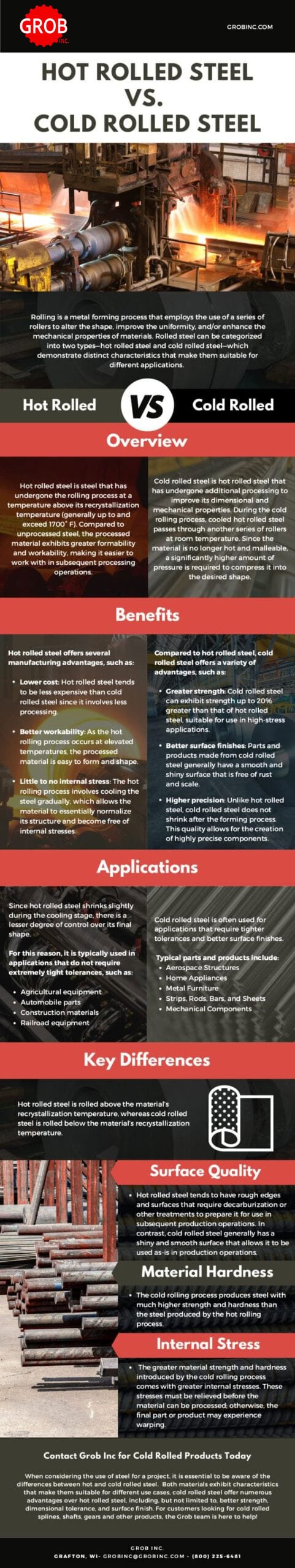

Rolling is a metal forming process that employs the use of a series of rollers to alter the shape, improve the uniformity, and/or enhance the mechanical properties of materials. Rolled steel can be categorized into two types—hot rolled steel and cold rolled steel—which demonstrate distinct characteristics that make them suitable for different applications. When choosing a rolled steel material for a project, it is important to be aware of the differences between the two types and how they affect their performance.

An Overview of Hot Rolled Steel

Hot rolled steel is steel that has undergone the rolling process at a temperature above its recrystallization temperature (usually 1700° F or greater). Compared to unprocessed steel, the processed material exhibits greater formability and workability, making it easier to work with in subsequent processing operations.

The hot rolling process starts with a large, rectangular slab of metal referred to as a billet. First, the billet is heated and compressed into a large roll. While still hot, it passes through a series of rotating rollers to achieve the desired dimensions. In sheet metal production operations, the rolled steel is then wound into coiled rolls and left to cool. In production operations involving other forms, the processed material is cut into the specified units and packaged.

Benefits of Hot Rolled Steel

Hot rolled steel offers several manufacturing advantages, such as:

- Lower cost: Hot rolled steel tends to be less expensive than cold rolled steel since it involves less processing.

- Better workability: As the hot rolling process occurs at elevated temperatures, the processed material is easy to form and shape.

- Little to no internal stress: The hot rolling process involves cooling the steel gradually, which allows the material to essentially normalize its structure and become free of internal stresses.

Applications of Hot Rolled Steel

Since hot rolled steel shrinks slightly during the cooling stage, there is a lesser degree of control over its final shape. For this reason, it is typically used in applications that do not require extremely tight tolerances, such as:

- Agricultural equipment

- Automobile parts (e.g., frames and wheel rims)

- Construction materials (e.g., I-beams)

- Railroad equipment (e.g., tracks and railcar components)

An Overview of Cold Rolled Steel

Cold rolled steel is hot rolled steel that has undergone additional processing to improve its dimensional and mechanical properties. During the cold rolling process, cooled hot rolled steel passes through another series of rollers at room temperature. Since the material is no longer hot and malleable, a significantly higher amount of pressure is required to compress it into the desired shape. While this process can be more labor-intensive and expensive than the hot rolling process, it can achieve tighter dimensional tolerances and better surface qualities.

Benefits of Cold Rolled Steel

Compared to hot rolled steel, cold rolled steel offers a variety of advantages, such as:

- Greater strength: Cold rolled steel can exhibit strength up to 20% greater than that of hot rolled steel, which makes it more suitable for use in high-stress applications.

- Better surface finishes: Parts and products made from cold rolled steel generally have a smooth and shiny surface that is free of rust and scale.

- Higher precision: Unlike hot rolled steel, cold rolled steel does not shrink after the forming process. This quality allows for the creation of highly precise components that require little to no secondary processing.

Applications of Cold Rolled Steel

Cold rolled steel is often used for applications that require tighter tolerances and better surface finishes. Typical parts and products include:

- Aerospace structures

- Home appliances

- Metal furniture

- Strips, rods, bars, and sheets

- Mechanical Components

Key Differences Between Hot Rolled Steel and Cold Rolled Steel

As indicated above, the main difference between hot rolled steel and cold rolled steel is the temperature at which they are processed. Hot rolled steel is rolled above the material’s recrystallization temperature, whereas cold rolled steel is rolled below the material’s recrystallization temperature. Beyond this quality, there are a few other distinctions between the two materials, including in regard to the following:

- Surface quality. Hot rolled steel tends to have rough edges and surfaces that require decarburization or other treatments to prepare it for use in subsequent production operations. In contrast, cold rolled steel generally has a shiny and smooth surface that allows it to be used as-is in production operations.

- Material hardness. The cold rolling process produces steel with much higher strength and hardness than the steel produced by the hot rolling process.

- Internal stress. The greater material strength and hardness introduced by the cold rolling process comes with greater internal stresses. These stresses must be relieved before the material can be processed; otherwise, the final part or product may experience warping.

These two steel types should not be confused with the technical specifications or grades used to classify steel by composition or physical characteristics. Steel can be hot rolled or cold rolled regardless of its metallurgical specifications or grade.

When evaluating steel options for a project, it is important to keep in mind that some materials will work better than others for certain purposes. Understanding which type of steel offers the right properties for a given application can prevent overspending on raw materials and save time in the long run.

Cold Forming Services at Grob Inc.

Cold forming is an umbrella term that encompasses several forming processes that occur at or near room temperature, such as bending, drawing, and rolling. At Grob Inc, we specialize in cold rolling specialized profiles onto bar stock.

Our team manufactures cold rolled parts and products from a variety of metals, such as aluminum, naval brass, stainless steel, and other steel alloys. The finished components demonstrate higher tensile strength, greater material hardness, tighter dimensional tolerances, and a better surface finish than ones produced through high-heat forming methods. Additionally, since the cold rolling process involves the displacement of material—rather than the removal of material—our production operations occur with a better material usage to waste ratio.

Some of the parts and products we regularly produce in these operations include:

- Gears

- Spline Shafts

- Timing pulleys

For additional information about our cold forming capabilities, check out our cold forming process page.

Contact the Cold Rolled Steel Experts at Grob Inc. Today

When considering the use of steel for a project, it is essential to be aware of the differences between hot and cold rolled steel. Both materials exhibit characteristics that make them suitable for different use cases, but cold rolled steel offer numerous advantages over hot rolled steel, including, but not limited to, better strength, dimensional tolerance, and surface finish. For customers looking for a cold rolling partner, the Grob team is here to help.

By partnering with us for their cold rolled metal needs, our customers benefit from our:

- Extensive industry experience. Our company has been in the cold forming business since the 1950s.

- Large-scale manufacturing facility. We maintain a 100,000 square foot manufacturing equipped with more than 60 engineers and technicians.

- Broad standard and custom product selection. Our customers can choose from over 2,100 standard profiles in standard and non-standard sizes for components such as bushings, gears, shafts, sleeves, splines, and timing pulleys. Additionally, we offer custom profile solutions to customers with highly specific or unique needs.

To find out more about our standard and custom cold rolling capabilities or discuss your next project with one of our experts, contact us today.