Most commonly used to transfer power and torque from one part of a mechanical system to another, shafts are long, cylindrical components that serve an assortment of applications, depending on the mechanical system’s needs. Shafts can be comprised of varying materials and fabricated in different lengths and diameters to fit the needs of the final product. They also vary by type, such as splined and keyed.

In this blog post, we will explore the differences between two similar types, splined shafts and keyed shafts, diving into their advantages, shortcomings, styles, and characteristics.

Splined Shafts

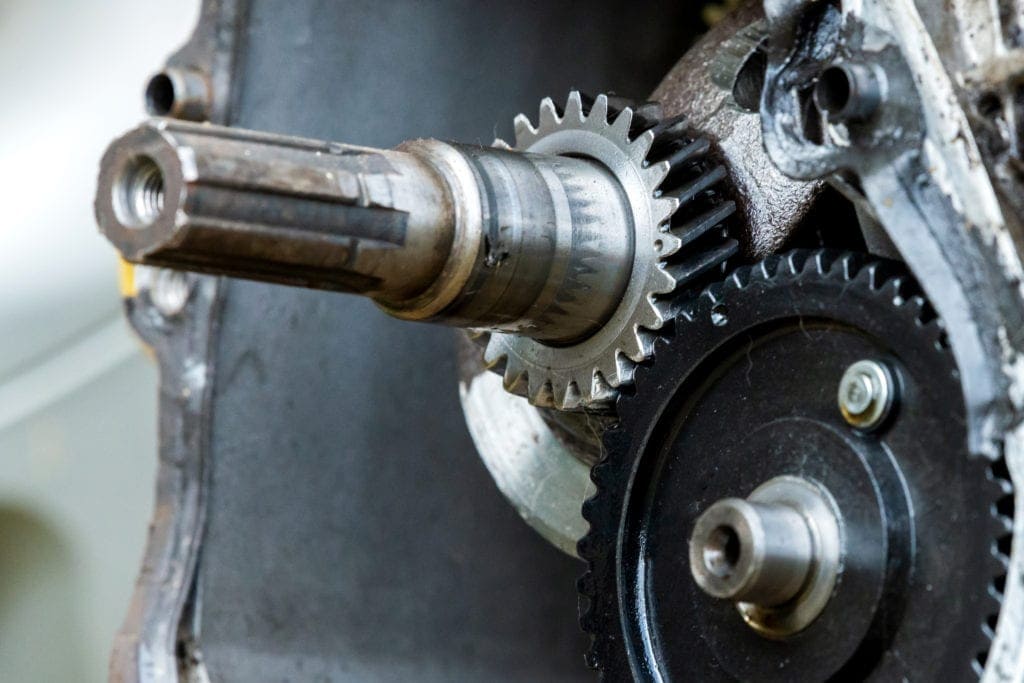

Containing teeth or ridges that allow them to mate with other components, splined shafts are primarily used to transfer torque throughout mechanical drive systems while allowing for linear motion, such as those found in vehicles. Normally, they are composed of different metals depending on the localized stresses they are expected to undergo. Their teeth or ridges equally distribute circumferential force to a mated component, facilitating a uniform transfer of torque between the mated pair. This also helps to prolong the lifecycle of the parts.

Like other types of shafts, they are available in a collection of styles, including ball splines, crowned splines, helical splines, serrations, and parallel splines.

Different styles of splined shafts can be chosen for an application based on how well they best fit into its mechanical system. These different styles can be chosen for characteristics, such as the design of their teeth or ridges, their overall strength, their transfer of rotational concentricity, their ability to slide, and their tolerance for misalignment.

Keyed Shafts

A keyed shaft, on the other hand, is a shaft containing a key seat along with a corresponding key. Similar to how a traditional lock and key operate, the key is situated into the key seat, which allows the keyed shaft to mate with the keyway found on another component, facilitating the connection between the two components. In mechanical engineering, the key shaft is employed to join a rotating machine element to a shaft. Without the key, the two components would have no way of interacting with one another, but, when mated, the two components work in unison, allowing for axial movement between the pair.

Like splined shafts, keyed shafts are available in a variety of materials, lengths, and diameters, and their keys are available in different styles, such as round, saddle, sunk, and tangent.

Unlike splined shafts, which are more likely to resist everyday wear and tear due to their form, the design and function of keyed shafts make them prone to attrition. In most industries, they are slowly being phased out in favor of splined shafts, which offer more in terms of higher rotational speeds, better rotating shaft balance, and superior torque delivery. Key shafts are usually found in machines, motors, and gear-and-pulley systems where the union is more permanent.

Splined Shafts from Grob, Inc.

Splined shafts offer advantages that keyed shafts are unable to match, and without a major increase in price, too. As a result, splined shafts are increasingly becoming preferred over keyed shafts for most applications.

At Grob, we manufacture both industry standard spline shafts and custom spline shafts. In our almost 90 years in the industry, we’ve come to understand that some situations are unique and require a custom product to be most effective. Both our standard and custom splined shafts offer a large contact area to help evenly distribute the load experienced by the shafts, increasing their longevity and efficacy.

For more information on our available splined shafts, including to request a quote for a custom project, please contact us today.