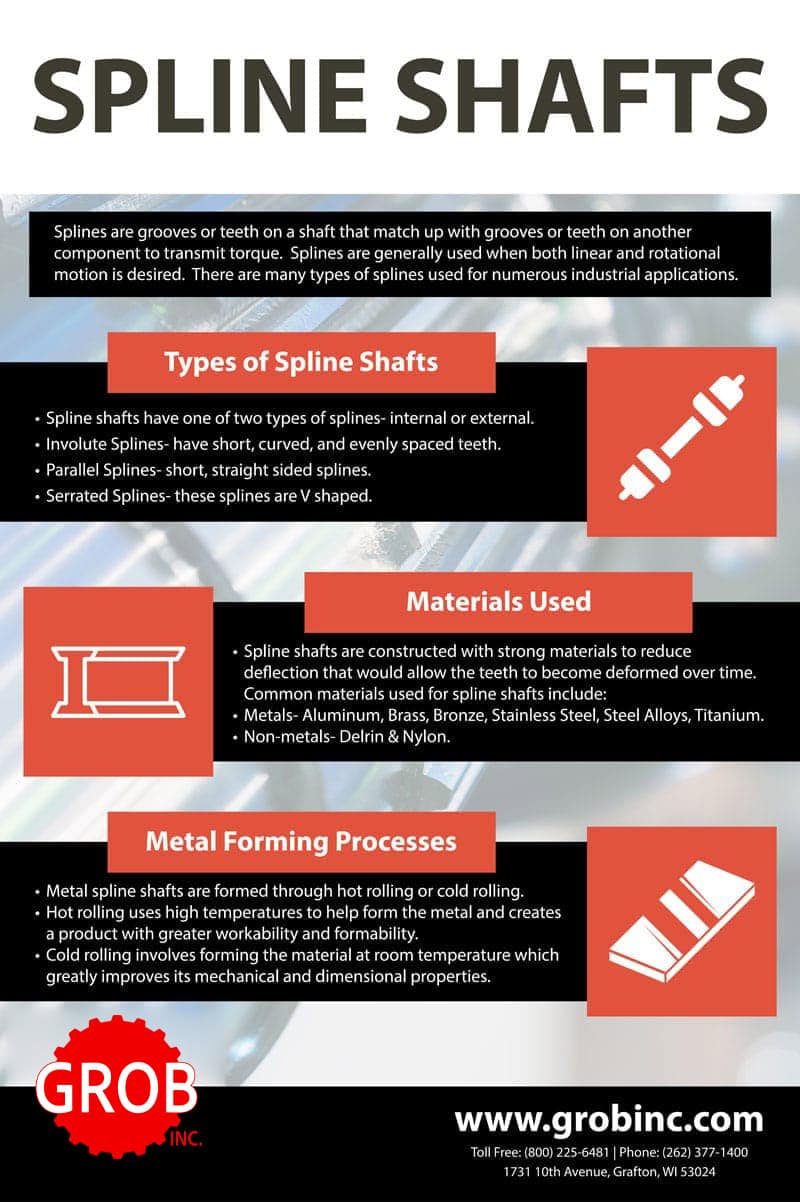

Splines are grooves or teeth on a shaft that match up with grooves or teeth on another component to transmit torque. Splines are generally used when both linear and rotational motion is desired. There are various types of splines used for numerous industrial applications.

Spline Applications in Manufacturing

Multiple different industrial processes use splines to transfer torque along complex configurations. Some common applications include:

- Heavy Machinery: Spline shafts are frequently used in automobiles, aviation, and earth moving machinery as they can handle high rotation speeds to deliver torque. Unlike alternative shafts like key shafts, spline shafts can deliver more torque due to the even distribution of the load across all the teeth or grooves.

- Consumer Goods Many manufactured products include splines such as bicycles, motorized vehicles, and more.

- Industrial Applications: Many industries utilize splines or products with splines such as, commercial, defense, general industry and equipment, energy, healthcare, musical instrument, leisure, power tool, transportation, and scientific research.

Spline Shaft Types and Considerations

To best meet the needs of different industrial processes or equipment, Grob Inc. can produce spline shafts with a wide variety of shapes, lengths, and design considerations. It’s important to consider surrounding mated parts, torque demands, and size requirements when choosing the type of spline shaft for your application.

Types of Spline Shafts

Spline shafts are designed to have one of two types of splines: internal or external. These types can be used in combinations to transfer torque through a system. There are numerous types of spline shafts, including, involute splines, which have short, curved, and evenly spaced teeth; parallel splines, which are short, straight sided splines; serrated splines, which are V shaped; and helical splines, which are built for optimal load sharing. Each type of spline has its own advantages and disadvantages, involute splines for example, provide more surface contact for a better transfer of torque, and their design reduces the risk of misalignment with mating pieces.

While spline shafts consist of a single part with grooves cut or rolled into the material, key shafts feature two parts: the shaft with the appropriate keyway, and the key itself. Splined shafts provide a more uniform and controlled transfer or torque.

Materials Used for Spline Shafts

Spline shafts are constructed with strong materials to reduce deflection that would allow the teeth to become deformed over time. Common materials used for spline shafts include:

Metals:

- Aluminum

- Brass

- Bronze

- Stainless Steel

- Steel Alloys

- Titanium

Non Metals

- Delrin

- Nylon

Metal Forming Processes Used

Metal spline shafts are formed through either hot rolling or cold rolling. Both processes use pressure to roll and shape the metal into the form required for the specific spline design. However hot rolling uses high temperatures to help form the metal and creates a product with greater workability and formability. Cold rolling involves forming the material at room temperature which greatly improves its mechanical and dimensional properties. These properties include greater tensile strength, improved surface finishes, and higher precision.

Standard and Custom Spline Shafts from Grob Inc.

Splines are important for manufacturing a variety of products and machinery across several industries. Grob Inc. offers high quality standard and custom spline shafts with an emphasis on affordability, customer service, and value. To learn more about our capabilities, contact us today.